There are so many misconceptions about wood floors. We almost always have to hold a mini-seminar on all the different options that are available to anyone wanting a wood floor. Here is what you need to know.

First, there are two basic ways to buy wood floors that concern the finish:

Prefinished hardwood flooring has been finished - sanded, stained, and coated with polyurethane -- in a factory. All you need to do is install it (cut and nail or glue it to the subfloor) and it is done. Prefinished floors can be used immediately after installation is completed.

Unfinished, or site-finished, flooring is raw hardwood that must first be installed and then sanded, stained & urethane coated on site. Site finishing is a multiple day process, and the floors must be allowed to cure after the actual work is completed before they can be used. Site finished accounts for about 25% of all installations today.

Unfinished, or site-finished, flooring is raw hardwood that must first be installed and then sanded, stained & urethane coated on site. Site finishing is a multiple day process, and the floors must be allowed to cure after the actual work is completed before they can be used. Site finished accounts for about 25% of all installations today.

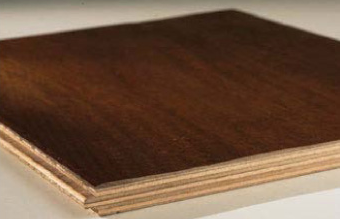

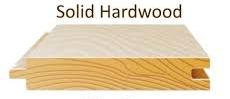

The next category that needs definition is Engineered Hardwoods versus Solid Hardwoods. Many people believe that solid wood floors are better than engineered wood floors, but it's important to note that both are made using real wood. In addition, once installed, they will look the same.

As the name implies, solid hardwood is one solid piece of wood, all the way through. It is almost always 3/4" in thickness. Engineered hardwood flooring is done in layers. The top layer is a hardwood veneer and then beneath that, there are layers (or plies) of wood. Generally, these plies are perpendicular in direction and laminated together (similar to plywood), and generally (but not always), these plies are made of wood, although they are not necessarily the same species as the top layer. The thickness of the top veneer can vary, and generally higher quality engineered woods have a thicker top layer, and cheaper ones have a thin one.

Engineered wood floors are real wood floors. They are manufactured using multiple layers of wood or wood composite. With engineered wood flooring, the only non-wood components used to make them are the adhesives used to bind the layers together, and the finish that is applied to the top veneer to protect the wood. Depending on the thickness of the veneer that tops the flooring, the quality of flooring used, and how well you maintain your floors, engineered hardwood can last a lifetime. All 3 factors play a big role in determining the longevity of any floor in your home.

Engineered wood floors are real wood floors. They are manufactured using multiple layers of wood or wood composite. With engineered wood flooring, the only non-wood components used to make them are the adhesives used to bind the layers together, and the finish that is applied to the top veneer to protect the wood. Depending on the thickness of the veneer that tops the flooring, the quality of flooring used, and how well you maintain your floors, engineered hardwood can last a lifetime. All 3 factors play a big role in determining the longevity of any floor in your home.

Solid wood floors are just that: They are a solid piece of wood. Solid wood can be installed prefinished or site finished, just like engineered floors. Solid floors can be sanded and stained multiple times, until you actually reach the level of the nails used to install them. We find, however, that with normal wear and good maintenance, most wood floors do not NEED to be sanded but about every 20 years. You may WANT to sand and stain in a shorter time frame, according to color trends and your taste.

Neither floor type can be called best in a global sense. But each has strong points and a few deficits in individual categories.

Refinishing--- is one of the greatest differences between engineered and solid wood flooring. Engineered wood can be sanded only until the upper layer wears away, normally once or twice. Solid wood can be sanded numerous times. Eventually, even solid hardwood will become too thin after years of sanding, compromising its structural integrity.

Refinishing--- is one of the greatest differences between engineered and solid wood flooring. Engineered wood can be sanded only until the upper layer wears away, normally once or twice. Solid wood can be sanded numerous times. Eventually, even solid hardwood will become too thin after years of sanding, compromising its structural integrity.

Installation--- Engineered wood is easier than solid hardwood as you have a greater range of installation methods, including stapling or nailing, floating, or glue. Solid wood flooring is nailed or stapled down.

Resale Value--- Because engineered wood floors are real wood, they can be advertised as such in real estate marketing materials, making them more attractive to buyers. As long as the floor is in good shape, it is on equal terms with solid wood flooring in terms of resale value.

Durability--- Engineered wood floors are durable, but not comparable to solid wood over a very long period of time. Yet its ability to hold up to limited moisture helps bring up its durability rating.Well-maintained solid hardwood flooring will last for decades. Moisture is the enemy of this organic product. Wood floors do stand a chance of being salvaged after flooding, but they will never perfectly return to their former shape.

Durability--- Engineered wood floors are durable, but not comparable to solid wood over a very long period of time. Yet its ability to hold up to limited moisture helps bring up its durability rating.Well-maintained solid hardwood flooring will last for decades. Moisture is the enemy of this organic product. Wood floors do stand a chance of being salvaged after flooding, but they will never perfectly return to their former shape.

Moisture--- Engineered wood is better than solid hardwood at dealing with moisture. Its core is more dimensionally stable, meaning that it warps and expands less easily upon contact with moisture than solid wood. Solid hardwood is never recommended for bathrooms, basements, or other areas where moisture is prevalent or even expected. Still, solid hardwood can resist some moisture.

Hardness--- Exotic hardwoods tend to be the most durable, including many of the South American or Indonesian exotics, as well as maple and walnut. Hardness ranges from extremely soft and appropriate only for very light traffic area to extremely tough hardwoods (for example, Brazilian Walnut).

Be aware that most wide plank hardwoods (6" or wider) are engineered, not solid. Also know that if you are interested in a distresses or scraped floor, the cost will be significantly lower in engineered than in solid construction.

Something New In Store! We are now carrying 2 lines of Oil Finish wood floors.

Should you choose oiled finish hardwood floors? Selecting the appropriate finish for your hardwood flooring is not only essential to enhancing the natural beauty of the wood, but to ensuring that the floors remain protected from the wear and tear of everyday living.

Should you choose oiled finish hardwood floors? Selecting the appropriate finish for your hardwood flooring is not only essential to enhancing the natural beauty of the wood, but to ensuring that the floors remain protected from the wear and tear of everyday living.

It is important to distinguish the difference between wood stain and wood finish. Wood stain simply refers to a color element, typically liquid, that is applied to the wood that dyes the wood a particular color. It contains absolutely no protective barrier for your wood flooring. Wood finish, on the other hand, protects a floor from damage by providing a "shield" on the top layer.

Now that we know the difference between staining and finishing, which finish is the best for your application?

Historically, urethane finishes have been tremendously popular due to their extreme durability. Whether site finished or factory finished (prefinished), urethane finishes are the most damage resistant. However, this durability comes with several noteworthy drawbacks. Firstly, they are difficult to re coat because the finish is so hard.

Secondly, urethane finished floors look the best the day they are installed and continue to get scratched, scuffed and worn over time until they have to be re coated or refinished. Damage to a urethane floor is easily identifiable by the highly visible white scratches that will inevitably appear. In order to repair the finish, you must remove all furniture from the space to apply an even uniform fresh coat of finish.

Oil finishes have increased in popularity recently mainly due to a movement towards a low-sheen, chic and natural matte aesthetic. Oil finished floors are excellent for bringing out the natural beauty of your selected wood specie. Unlike polyurethane finished floors, oiled floors are very easy to repair if damage is done. When scratches occur on oiled floors, you can buff and blend them away very easily without removing the furnishings. Because of the flexibility to repair damages on oiled floors, if you are someone that does a lot of entertaining, an oiled floor is an excellent selection as it is easy to return the floor to pristine condition.

Maintenance is another key in extending the product life cycle of your wood floor. Urethane and oiled floors are maintained in different ways. When specifying the finish type, be sure to understand what kind of cleaning and maintenance will be required.

A urethane floor finish should be dry mopped or vacuumed. Seldom will it ever be damped mopped. With excessive damp mopping, it is possible for contaminants to create a haze on the finish. Additionally, these contaminants may present adhesion issues when it becomes time to re coat. In contrast, oil floor finishes may be damp mopped with a soap and water solution. In conclusion, oiled finish hardwood floors offer a beautiful matte look, with less headache when it comes time to repair the inevitable scratches that will occur during your floor's lifespan. Come in and see our gorgeous new oil finish floors!

We hope this has clarified a few points in wood floors, and that we have helped make your wood floor shopping experience easier.

Save The Date

Mark your calendar now for our next event on May 14 from 4 till 7 pm-- a Flooring Fiesta. We'll have informative seminars plus our vendor representatives here to answer your product questions. The Margarita Man will be here too along with a taco buffet. As usual, there will be prizes, and as always, there will be fun!

Mark your calendar now for our next event on May 14 from 4 till 7 pm-- a Flooring Fiesta. We'll have informative seminars plus our vendor representatives here to answer your product questions. The Margarita Man will be here too along with a taco buffet. As usual, there will be prizes, and as always, there will be fun!

No comments:

Post a Comment